BMW 760i Repairs page 2

Getting it on my Quickjack

Under car inspection

Oil filter access cover

Headlight restoration

Heater Control valve

External Power Supply for programming

New engine mounts

Transmission mounts

Transmission service (bridge seals, fluid and filter)

Replace drive shaft flex coupling (Guibo)

Steering Angle Sensor repair. (SZL) updated Feb 2025

1. Getting the car up on my Quickjack

My Quickjack is a model BL5000SLX and not quite long enough to reach the lift points on this 760i (60" vs. 65" on 760i). Quickjack now sells an extension frame that sits on top of the Quickjack but these were sold out when I needed them so I decided to try a pair of 2x6 and it works great. In the pic below added a bit of extra support under the front wheels just in case but it seems not to be necessary.

2. Under car inspection

I really should have done this before I purchased the car but there were no big surprises... just a lot of oily crud which I believe is from the valve cover gaskets.

The front control arm bushings are on their way out as you can see below. I'm not sure what brand these are as there is no makings on the control arms so I'll replace the complete arms even though it is possible to press in new bushings. These have been replaced at least once as evidenced by a large hole knocked into the wall of each brake cooling duct to allow the bolt to withdraw (mechanic too lazy to loosen a few screws and move the brake duct out of the way). These bushings are a very common failure on all BMW's and considered a consumable part.

The PS reservoir to pump hose is sweating a little at this connection. I'll trim the hose and add a new clamp if it is long enough..

Drivers side front splash shield is broken and will be replaced (~$30).

Back of the engine and transmission look fairly dry - nothing to worry about here.

I removed the transmission cover to inspect and all looked well there too. Note the front and rear sub-frames are all aluminum on this car.

The boot on one end of the steering rack is nicked and leaking a small amount of grease. I'll patch this with a silicone sealer.

A sloppy mechanic has clearly worked on this car in the past; here's just one example... the fan shroud is not correctly seated and you can see the front shroud is also not fitted correctly! I've also found missing hardware, both fresh air ducts broken, mismatched hardware and many more instances to follow.

3. Oil Filter access cover

E65's shipped to the USA do not include an access cover for the oil filter but they are available. I have no idea why but I decided to make my own from a piece of scrap aluminum...

4. Headlight restoration

I cleaned up both headlights with a Harbor Freight headlight refinishing kit...

They are not perfect, but a lot better than they were.

For reference here is a pic of the back of the headlight.

The soft rubber surrounding part of the headlight was rotten and falling apart so I replaced it with some closed cell foam strip but you can buy a replacement piece for only $15 which I may eventually do.

After sanding and polishing them, I applied a ceramic coating.

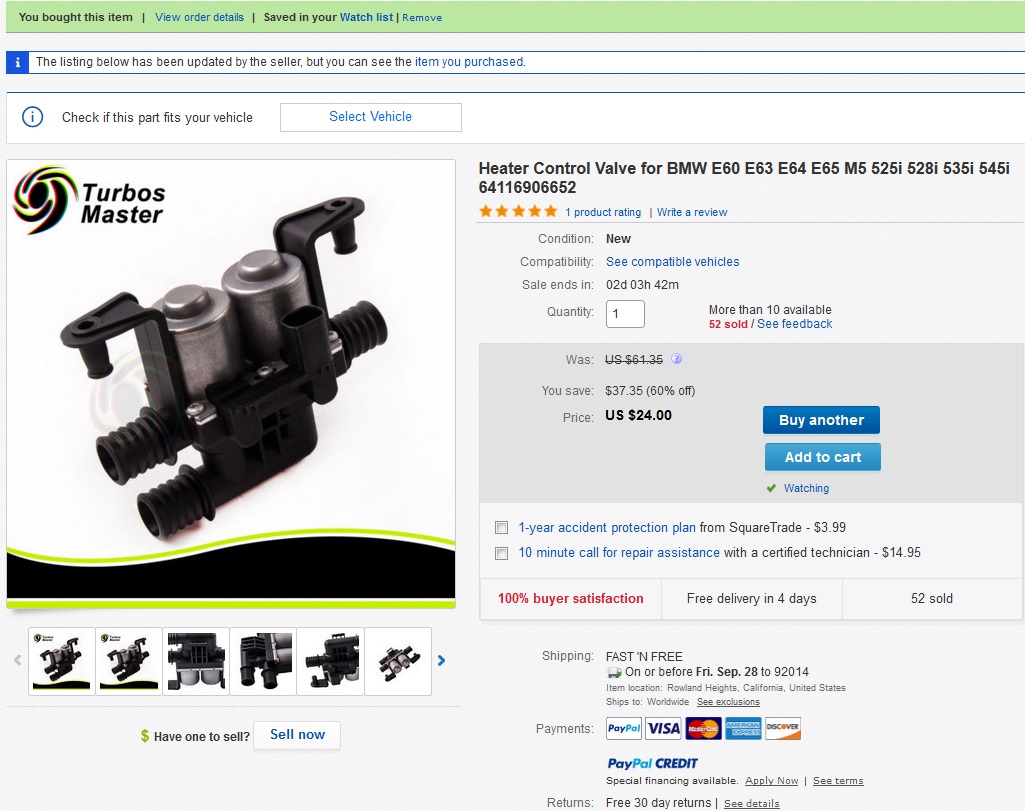

5. Heater Control Valve

The rubber seals in these valves perish with age. You can buy replacement seals on Ebay for $35 a set but there is a cheaper solution...

First I disassembled and cleaned it (just remove 6 x screws).

You can buy a complete replacement on Ebay for $24 (cheapest I could find at the time)!

It's pretty much an exact copy of the original but the materials are not quite the same... the plastic body feels a bit softer. All the internal and external dimensions are exactly same as the original part!

It also has the exact same set of seals in it that you can buy on Ebay for $35 (just for the seals)!

I decided to remove the seals from the $24 valve and install them in my original part. Not shown is a couple of seals that sit in the black plastic housing - you pull out the 2 x beige colored plastic tubes to get to those and a couple of o-rings.

The cone shaped plungers are an interference fit on the plunger shafts - just pull them off. To re-install it is best to use a small press (I used my drill press), only light pressure is needed to re-install them. Pic below shows the new seals installed on my original plungers.

Here are the leftover parts from the new valve.

My re-assembled Heater control valve with new seals below.

I used a 12V source to test...

Pin 1 +12V

Pin 2 RTN (solenoid 1)

Pin 3 RTN (solenoid 2)

Or you could simply use the $24 part as is... it's a great deal compared to the price of an oem replacement and of surprisingly good quality for the money!

6. External Power Supply for programming

When doing any programming on this car it is necessary to ensure the battery voltage is always > 12.6V. An external power supply is recommended to ensure the battery voltage does not drop which could corrupt the module being programmed.

The Power Supply below is a modified computer server supply and is capable of 13.5V @ >60A ! It is a model DPS-800GB that can be found on Ebay for ~ $25. To power up you must join P31 to P34 and to raise the voltage to 13.5V connect a 1.2K resistor from P32 to ground. I've got about 3ft of heavy monster cable soldered to the output pins.

7. Engine mount replacement

As you can see in the picture below, the drivers side engine mount has collapsed. The engine is now close to an inch lower than it should be on this side!

Its a bit harder to see the passenger side (below) but it appears to be in much better shape, perhaps 1/4" lower than when new.

Here's what the new mounts looks like. Only OEM BMW parts are available (no cheaper aftermarket).

Here's my receipt for these (the best deal I could find).

The BMW service manual states to suspend the engine and drop the front sub-frame to replace these but on every other BMW I've owned I've been able to replace these by raising each side of the engine. So I attempted the same here...

I already have the alternator housing removed which gives much better access to the drivers side engine mount, in fact I'm not sure you could do this job without removing this housing. I also had to disconnect the refrigerant line from top of A/C compressor as there is no way to extract the passenger side engine mount otherwise. I also loosened the exhaust connections below the cats on each side so that raising the engine would not put undue stress on the exhaust system. I have most of the top end of the motor removed which gave good access all around.

There is no easy place to jack up the motor due to many hoses running along the bottom of it. I thought about jacking the steel sump but is fairly far back on the motor so I made a couple of wooden jigs allowing me to place a jack under each of the front sides of the engine where the casings are strong. This worked great...

The plywood jigs are sitting on the 3 front side bolts on each side of the engine and held steady with a piece of aluminum angle bolted to the motor. For the passenger side I also had to remove the 2 x hydraulic hoses connecting to the sway bar to make room.

The refrigerant line must be disconnected from top of compressor and moved to the side to allow room to remove and install the passenger side mount. Since I already have the front of the engine torn apart, the A/C system was already discharged.

The engine must be raised almost 2 inches to get the mounts out and the new ones in.

Here's what it looks like with the new engine mounts in place. The engine is now supported by the rubber mount where before it was sitting directly on the engine mount metal body.

Both the old mounts were original (Jun 2005 date code). You can see the drivers side is completely destroyed! The passenger side mount on the left is still in one piece you can see it is also cracked and sagged..

When jacking the front of the motor to replace the engine mounts it did not act as I expected... jacking one side raised only that side, jacking the other raised both sides. This was an indication the transmission mounts are also damaged...

8. Transmission mount replacement

To do this the exhaust system has to come down. I used a transmission jacket and buckets to gradually lower it... it's very heavy (especially the end with the mufflers) and not an easy job to do by yourself. Then you must remove the heat shield surrounding the drive shaft and to facilitate this, remove one of the plastic covers running down the underside of the car.

Then you can see the transmission mounts. I used my Harbor Freight transmission jack to take the weight off the mounts (I used a rubber pad between the jack and transmission pan).

And as expected... one of the transmission mounts has completed separated!

With the transmission supported, it is a simple job to drop this cross member and replace the mounts. I marked the bolt positions in the base to ensure I re-installed it in exactly the same position it was (centered).

New mounts...and a comparison with one old one.

9. Transmission service

This is preventive maintenance... I replaced the valve body bridge seals, the mechatronics seal, installed a new OEM filter and fresh transmission fluid.

This is a messy job but quite straightforward...

First loosen the fill plug - mine was tight and required a breaker bar to loosen.

Then remove the drain plug and drain the oil. I recovered ~ 6 litres of fluid from the pan

Then loosen bolts and drop the plastic pan. Check the 2 x magnets for metal shavings (mine look fine, just some very fine material which is normal). There's a date stamped on the inside of the pan... 'May 2011' which indicates this transmission has been serviced by someone already!

Pull the white tab down to release the mechatronics sleeve and then pry it out with a large flat screwdriver. Access is tight but a lot easier with the exhaust removed. The date code on the Mechatronics sleeve was 2011 also, so appears this was also replaced.

Note the position of the 'park' actuator. This is important when you put it back together!

Then loosen the 10 large bolts on valve body and lower it.

The Valve body weighs about 10 lb.

The red circled areas show contact points with the bridge seals that will be replaced..

Here you can see how the mechatronics sleeve seals the transmission connector. Pushing the white tab up locks it in place.

At this point, with such oily hands I stopped taking pics.

The bridge seals are retained in the transmission body. The 4 x short tubes are best removed with a pair of needle nose pliers... grab the inside lip of the seal and pull down. The main bridge seal with 2 x rectangular openings just pops off. Date code on mine was 2005 so likely original but was in excellent condition. Ignore the debris in the oil pan - this pic was taken after I dumped this and then retrieved it to get a picture.

After replacing the bridge seals it all goes back together... observe the tightening sequence below (8Nm) when re-installing the valve body and remember to make sure the park lever is engaged correctly.

All the time you are working on the transmission expect oil to keep dripping so I keep a large tub underneath it. I also disconnected the transmission cooler and drained it, and I blew out the oil in the return pipe. All together I captured 8.2 liters of transmission oil. Total capacity is about 10 liters, the rest is in the torque converter and will be flushed out when the car runs again.

This little tool makes it a bit easier to disconnect the transmission cooler lines.

The hose labeled 'TOP' is the return line to the transmission.

10. Drive shaft flex coupling (Guibo)

The original part didn't look bad but since I was already in there I decided to change it...

This replacement part cost ~$80 and is an oem part... if you look carefully you can see where the BMW logo and BMW part number have been scraped away!

This job is a lot easier if you remove the transmission mounts and cross-member. I have the transmission supported with a transmission jack and 2 x strips of wood running down each side of the transmission.

Be sure to mark everything so it go backs in the same orientation. All the bolts (x6) and nuts are 18mm. I needed a breaker bar to break them loose but the tightening torque is only 48Nm (35 ft/lb).

Once the bolts are out you remove the bolts from the center support bearing and then you can drop the drive shaft and detach the Guibo. Be sure to grease the center spindle before putting it back together. BMW recommends a special grease for this but I used a general purpose grease.

Here's the part I removed... you can see it is starting to deteriorate but not that bad (had no play in it).

Here it is all back together again... I touched up the paint on the drive shaft flange. It makes no sense to do this job without swapping out the transmission mounts also.

11. Steering Angle Sensor (SZL)

| ADR | Name | Status | Error | Error code | Likely cause | |

| 2 | SZL | Steering switch center | OK | 1 Error stored | 94E7 20 | Dirty contacts in steering angle sliders? |

To service the SZL module must first remove the airbag and steering wheel.

Remove the clock spring, stalks, cover and sliding contacts then cleaned the carbon tracks and surrounding area with Alcohol.

One of the sliding contacts was worn away.

I purchased some new contacts on Ebay for ~ $10 (2 pcs). I installed just one since I wasn't sure how well it would turn out.

It turned out much better than I expected... good as new! Wish I'd done them both!

After re-assembly and install back in the car I used Inpa to re-calibrate center position.

Updated Feb 2025...

The above repair lasted a few years but only 5,000 miles (I don't drive this car much).... I started to get error messages again.

I removed the Steering angle sensor again... it doesn't affect operation but the housing is looking a lot worse for wear!

The sliding contacts disintegrated...

So this time I went with a slightly different solution...

These are available inexpensive on Aliexpress. I purchased 2 sets for about $5 ea! Unfortunately they do not fit without a little fettling... there is a small recess on the underside mounting hole that is not quite large enough, I used a box cutter to carefully scrape away until it fit snugly. I used a couple of Aluminum pop rivets to secure them... I had to turn down the dia of the rivet to fit and did not use the popper, I splayed it out with a punch and small hammer.

I also applied some deoxit sliding contact cleaner to the carbon tracks (it has a lubricant in it). I'm hoping the lack of a lubricant is what killed my first repair.

I must say this new solution looks a lot better and no soldering is required. After reassembly and calibration (very simple in ISTA-D), all is well again.